Model OL - Miniature Liquid Level Sensor

- Compact Size

- Low Cost

- Reliability / Long Life switch life

- Can be used in wide range of liquids

- Perfect solution for standard assembly parts

General Description

These miniature liquid level sensors are designed for reliable operation in small tanks and containers. Their rugged design and careful engineering makes them suitable for OEM and large colume applications.

Operational Decription

These level sensors contain hermetically sealed reed switches in the stem and a permanent magnet in the float. As the float rises or falls with the level of the liquid, the reed switch activates by the magnet in the float. The operation of the switch, normally open or normally close, is easily changed by removing a retainer and inverting the float.

Conformity

Hygienic standards of Food, additives, etc. by Japan Food Research Laboratories.

Some of sensors are conformed by RoHS directive. Six materials such as Lead, Mercury, Hexavalent Chromium, Polybrominated Biphenyls, Polybrominated Diphenyl Ethers, and Cadmium are not contained to these products.

Typical Applications

- Typical applications include automatic vending machines, photocopiers, small collection tanks, miniature pumping stations, pilot plants and similar small-system applications.

- Controlling delivery of plating liquid Nickel plating liquid is used for surface treatment of electronic parts. The liquid is automatically fed into a plating bath with the OLV-2P detecting the upper and lower levels.

- Coffee extraction control. The OLV-5UN is mounted in the feeding water tank to detect the lower limit of the hot water. The OLV-5UN is suitable for food and pharmaceutical applications because the float joints are plasma welded and the surface is buffed smooth.

- Hot water control. The high temperature version of OLV-5 is the perfect solution for automatic water boiler tank to keep it always full. The wetted parts of OLV-5 are 316LSS float and 316SS stem/retainer, and it can withstand up to 120"C.

- OLV-2A

- Designed for water applications..

- OLV-2P:

-

Use in chemicals, food and portable water.

- OLV-2F

- Designed for applications involving corrosive chemicals and solvents.

- OLH-3

- Use in water only, horizontal mounting,0-ring seal provided.

- OLH-10:

- Use in chemicals, food and potable water,horizontal mounting.

** If purchasing replacement part, just give us the serial number and we will supply the correct part.**

Click on the buttons for full Nohken Specification catalog Sheet and User Manual

Catalog User Manual| Model | OLV-2A | OLV-2P | OLV-2F | OLV-5 | OLV-5UN | OLH-3, OLH-10 |

|---|---|---|---|---|---|---|

| Stem Material | Polyacetal | PP | PVDF | 316SS | 316SS | PP |

| Float Material | BUNA | Foamed PP | PVDF | 316LSS | 316LSS | PP* |

| Retainer Material | 316SS | PP | PVDF | 316SS | 316SS | PP |

| Operating Temperature | -10 to 90 ℃ | -10 to 100 ℃ | -10 to 100 ℃ | -10 to 90 ℃ ** | ||

| Maximum Pressure | 1MPa | 2MPa | 2MPa | 1MPa | ||

| Mounting Type | Vertical | Vertical | Horizontal | |||

| Switch Rating | 50VA | |||||

| Lead Wires | #22AWG, 300mm or 1000mm | |||||

| Minimum SG | 0.6 | 0.85 | 0.9 | 0.8 | ||

| Life Expectancy | 1 x 107 Operations | |||||

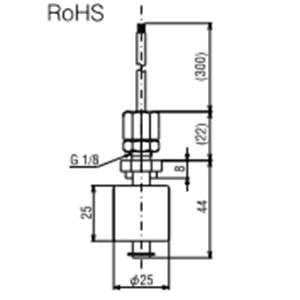

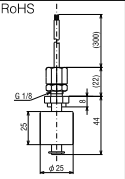

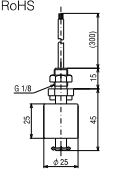

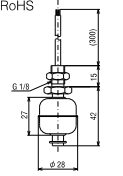

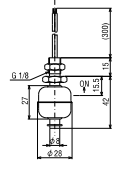

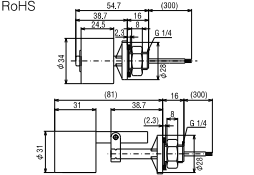

Technical drawings of Nohken Model OL Liquid Level Sensors.

For ordering replacement part, please supply full serial number

For replacement part, please provide full serial number to get exact part.