Model CG - New Capacitance Point Level Sensor

- One push adjusbnent by parameter

- Various function by microprocessor

- LCD for operation check

- Improved function for material build up

- Outstanding reliability

- No need to adjust in actual liquid

** If purchasing replacement part, just give us the serial number and we will supply the correct part.**

General Description

Conventional Radio Frequency and Admittance sensors are typically used as inexpensive solutions for point level detection, but they are often times unreliable. The model CG provides reliable, simple, and cost effective point level detection of liquids, solids, and adhesive conductive medium. Sophisticated application with fluids, operation conditions that requires periodical re-calibration with conventional simple sensors due to the deviation of working conditions like Fluid's chemical configuration, Humidity, Temperature, Resistance value factor, build up can not normally be covered with conventionally simple capacitance level sensors.

Our new model CG can work well both to simple fluids, difficult fluids, and sophisticated environment due to the patent pending circuitry.

Operational Description

The model CG consists of an oscillation circuit and a detection circuit. Both circuits synchronize at a constant 1.4MHz frequency in the air, f1=1/2 𝜋 √ LC.)

The frequency of detection circuit is changed from the air to in the medium by taking in the capacity of the medium, f2=1/2 𝜋 √ L(C+∆C)

The oscillation circuit automatically follows to synchronize with the frequency of detection circuit. When the resonance frequency shifts to the detection set point, the relay is energized.

Key Features and Benefits

- Patent circuitry: The CG consists of an oscillation circuit and a detection circuit, and the frequencies of these two circuits are automatically synchronized. This function provides Free from Initial Calibration, Wide Sensitivity Range, Resist Build up Problem, and Highly Stable Detection.

- One push adjustment by parameter Adjustment can be easily done by using 4 push button switches to select parameters and enter setting values. Without the tester or tool needed, the configuration error due to personal difference will be avoided.

- Improved function for material build up: Unlike the traditional sensors which utilize the change in voltage, the CG series detect the change in frequency caused by the change in capacitance value, resulting in minimizing the affection by build up

- No need to adjust in actual liquid When the application condition and the device model are the same, the sensor operates successfully with the same parameter values.

Click on the buttons for full Nohken Specification catalog Sheet and User Manual

Catalog User Manual| Model | CG-1NH | CG-2NH | CG-1FH | CG-2FH |

|---|---|---|---|---|

| Mounting | G3/4 * | JIS5K25A * | ||

| Supply Power | 100 to 240V AC ± 10%, 50/60Hz | |||

| Power Consumption | Approx. 5VA Max. | |||

| Relay Output | 1 SPDT, 250V 3A AC, 30V 3A DC (Resistive), C-NO: Normally Open contact, C-NC: Normally Closed contact | |||

| Detection Time Delay | Programmable between 0.0 to 25.5 seconds | |||

| Operating Temperature - Housing | -25 to 60 ℃ | |||

| Operating Temperature - Electrode | -25 to 60 ℃ | |||

| Maximum Pressure | 1MPa | |||

| Maximum Humidity | 95%RH | |||

| Housing Material | ADC12 | |||

| Electrode Material | 304SS | |||

| Insulator Material | PE | |||

| O Ring Material | FPM/FKM | |||

| Cable Entry | G1/2 | |||

| Protection | IP65 | |||

| Fail Safe | High or Low by program | |||

| Length of electrode | 250mm Standard, 2000mm Max. | |||

* Other size of mounting, R or NPT, is optionally available.

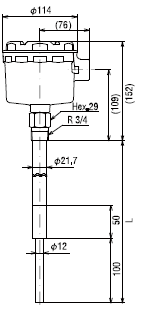

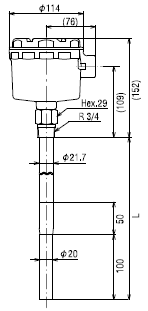

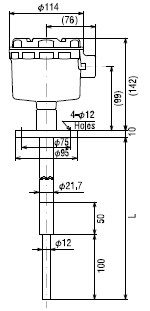

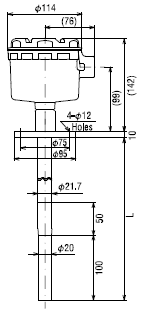

Technical drawings of Nohken Model CG New Capacitance Point Level Sensors.

For ordering replacement part, please supply full serial number

** If purchasing replacement part, just give us the serial number and we will supply the correct part.**